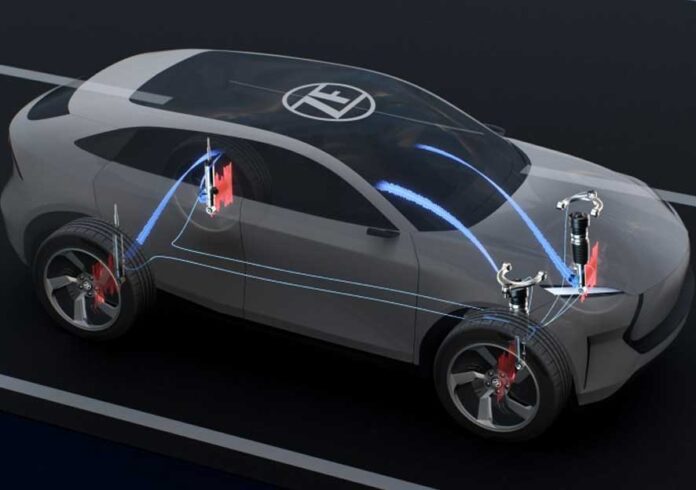

ZF has unveiled a glimpse into the future of in-vehicle acoustics with its new “Active Noise Reduction” software function, showcased at the Consumer Electronics Show (CES). Designed specifically for software-defined vehicles, the innovation significantly reduces tire noise inside the cabin—without the need for additional sound-insulating hardware.

Tire noise, often transmitted through chassis components such as control arms and dampers, is a common source of unwanted cabin disturbance. ZF’s solution tackles the issue directly at its source using a purely software-based approach integrated into the vehicle’s chassis system. By doing so, it minimizes intrusive noise while preserving interior comfort and driving refinement. ZF plans to further expand the application of this technology across additional chassis actuators in the future.

The system leverages ZF’s Smart Chassis Sensor, equipped with an integrated acceleration sensor, to precisely detect vibrations transferred from the tires through the chassis. These signals are processed by a proprietary algorithm capable of identifying tire cavity noise, typically occurring around 200 Hz. Once detected, the software generates a targeted counter-signal via ZF’s cubiX software platform, activating micro-adjustments in the valves of semi-active Continuous Damping Control (CDC) dampers. These micro-movements effectively cancel out noise without compromising the damper’s primary ride and handling performance.

“Active Noise Reduction is an excellent example of how we use smart algorithms to make ZF components even more efficient. This gives our semi-active CDC dampers a clear unique selling point in the market and sets new standards in comfort – without the need for any additional noise dampening hardware,” says Dr. Peter Holdmann, member of the ZF Board of Management and head of Division Chassis Solutions.

Intelligent dampers, brilliant quietness: this is what the future of chassis technology sounds like

The achievement of noise reduction is implemented purely on a software basis through intelligent control of the CDC dampers – without additional installation costs or space requirements. The current version of the technology achieves noise reductions of more than 3 dB today – which is a clearly audible difference for passengers. Up to 10 dB is possible in the future.

Active Noise Reduction can be adapted to different vehicle types and customer requirements via software. This creates a new market, particularly for lower-priced vehicles – as high-quality acoustic solutions with microphones or speakers have mostly been available only in luxury segments. Approximately 40 percent of all semi-active dampers worldwide already come from ZF, making the technology group the market leader. In view of the trend toward automated driving, ZF expects sales in this area to increase.

Active Noise Reduction part of Chassis 2.0

Series production of Active Noise Reduction is scheduled to start in 2028. In the future, the software function may also be used in other ZF actuators — for example, for active reduction of brake squeal or in the fully active damping system sMOTION.

“Thanks to our system expertise, we are able to offer our mechatronic actuators as true innovation drivers with the help of smart algorithms and we will extend our software-based control approach to other ZF actuators in the future. The goal for us is clear: mechatronic actuators that are capable of efficiently reducing both their own and external noise with the help of software,” explains Holdmann.

The new function fits perfectly into ZF’s Chassis 2.0 product strategy. Chassis 2.0 uses intelligent and networkable actuators to enable new chassis functions via software. It combines intelligent actuators such as brakes, steering, and damping, scalable electronic architectures (E/E), and innovative software solutions into a highly integrated, flexible system. “With our Chassis 2.0, we are laying the foundation for the software-defined vehicle,” says Holdmann.