The Volkswagen Group has achieved a major milestone by producing five million electric drive units worldwide. The achievement reflects the strength of its global production network spanning Győr, Kassel, Tianjin and Zuffenhausen, and underlines the Group’s systematic scale-up of e-mobility across brands and markets.

The milestone highlights the collaborative strength of Volkswagen Group Components’ international competence network. The Kassel plant alone ramped up electric drive production by approximately 24 per cent year-on-year in 2025, crossing 850,000 units.

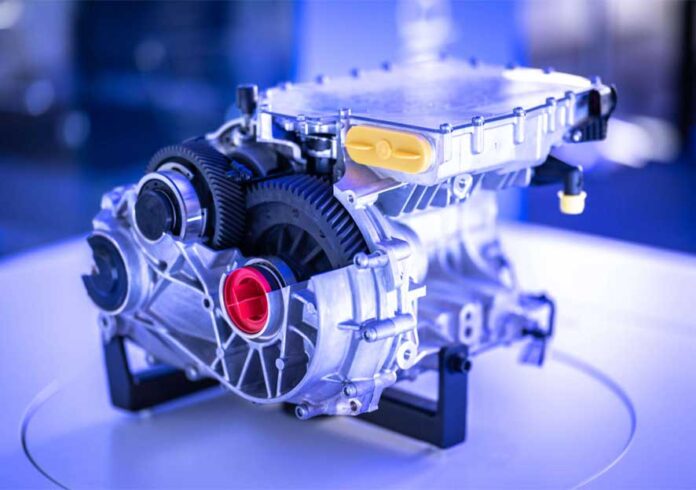

Thomas Schmall, Member of the Board of Management for Technology at Volkswagen Group, stated that reaching five million electric drives demonstrates the company’s leadership in both internal combustion engine (ICE) and battery electric vehicle (BEV) segments. He added that Volkswagen’s global development and production network enables end-to-end control over electric drivetrain technologies. With the development of its first in-house pulse inverter, the Group is taking control of a critical component often referred to as the “brain” of the electric drive system, strengthening technological independence and ensuring high performance standards.

APP550: Raising the Benchmark in the Volume Segment

Currently, the most widely used electric drive within the Group is the APP550. It powers models such as the Volkswagen ID. family, the Škoda Enyaq and the CUPRA Tavascan.

To date, one million APP550 units have been produced at the Kassel facility. The drive system sets new benchmarks in efficiency, driving dynamics and acoustic refinement within the Group’s volume segment.

Despite retaining the same dimensions as its predecessor, the APP550 delivers:

- Around 20 per cent lower energy consumption

- Approximately 75 per cent higher torque

- Around 40 per cent more power

In series production, the APP550 generates up to 240 kW and 560 Nm of torque. These improvements translate into enhanced range, stronger acceleration and reduced noise levels. A combined oil and water cooling system optimizes thermal management without the need for an additional pump, further improving overall efficiency.

The success of the APP550 reinforces Volkswagen Group’s commitment to maintaining high standards in electric vehicle development and manufacturing.

Integrated Development and In-House Pulse Inverter

Volkswagen Group’s integrated network oversees the complete development cycle of electric drive systems — from engineering and industrialization to power electronics and logistics. Facilities such as the Kassel plant play a pivotal role in bringing key technologies like electric drives and pulse inverters into series production.

A significant advancement is the introduction of the Group’s in-house developed pulse inverter. As a core component of electric drive systems, the inverter regulates energy flow between the battery and motor. By developing this technology internally, Volkswagen aims to accelerate product development timelines, reduce costs and decrease reliance on external suppliers.

APP290 and the Electric Urban Car Family

The newly developed APP290 electric motor will incorporate silicon carbide semiconductor technology, enhancing efficiency and improving real-world driving performance. This innovation will benefit upcoming models in the Electric Urban Car Family, including the ID. Polo, Škoda Epiq and CUPRA Raval.

The APP290, built on 400V architecture, is expected to be available in multiple performance variants ranging from 85 kW (116 PS) to 166 kW (226 PS), offering flexibility across different vehicle segments.