1. Please share about the journey of Euler Motors

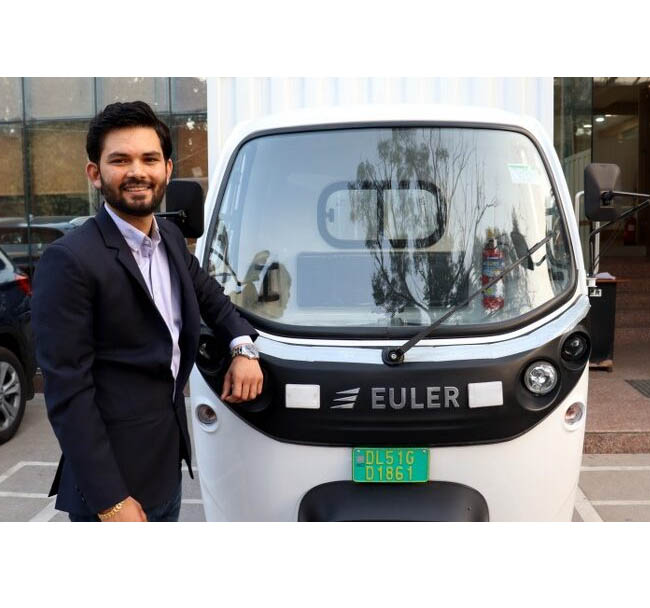

Euler Motors is an electric vehicle company, founded in 2018. At Euler, we have focused on building world-class commercial EVs, for India, from India – to enable a superior customer experience and lead the transition to EVs in the commercial segment.

In the last two years, Euler Motors has taken a lead in EV three-wheeler cargo segment innovation, with its powerful EV HiLoad, with the highest in industry load capacity of 688 kg, on road range of more than 150 km powered by a 12.4 KwH liquid-cooled battery. The vehicle comes with four different types of charging options, and expansive servicing options. HiLoad, is built to carry for any business application and is suited to operate for all weather and road conditions.

2. Can you tell us about your manufacturing process and technologies adopted by the company?

As mentioned above, Euler Motors has prioritised quality design and development to produce electric vehicles that meet the needs of Indian customers. Our state-of-the-art manufacturing facility in NCR Haryana, is capable of producing 3000 units per month, and includes a vehicle assembly line, BIW line and a battery manufacturing unit.

At Euler, since inception Euler Motors has focused on product quality and cost reduction through alternate sourcing, indigenization, and localization to ensure 100% output levels at a lower capital expenditure. From superior battery packs to product advancements, our focus is on continuous innovation to meet changing company requirements.

3. Kindly share Euler Motors’ strategies for localized EV manufacturing and value chain networks

At Euler Motors, we have actually pursued a localization strategy right from the start – where we brought in suppliers on board and worked closely with them to build the exact components we wanted for our vehicles. We also worked on developing our in-house capabilities for electronics, the parts which weren’t readily available. This helped us customize our electronics, which we could easily scale and integrate into other platforms – as and when needed.

Our localisation levels from a component standpoint stands at 95% today for the vehicle and 90% for our battery packs (with the exception of the cell).

4. Please share Euler Motors’ plans for this year.

We are already expanding our manufacturing, scaling to mass production and deployments. As we progress, we are ramping up production to manufacture 3000 vehicles per month within the next nine months.

Further, we continue to expand our manufacturing, and supply chain infrastructure, accelerating product development, augmenting talent across key functions in the organization, as well as expanding our distribution network, all while remaining committed to our core values of innovation, performance, and design.